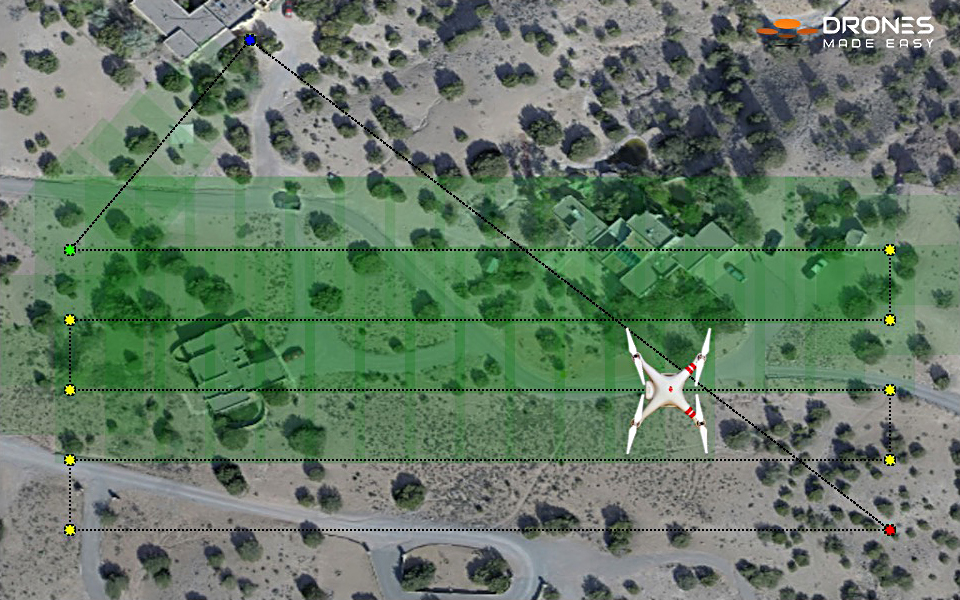

Top: The Maps Made Easy tool generates final image (above) by using 40 to 60 images Dirt Hugger takes with its drone, geolocating the images and “stitching” them together with existing maps. The resulting image allows Dirt Hugger to investigate measurements such as area and volume as seen in the placard. Image source: Maps Made Easy

Craig Coker

Unmanned Aerial Systems (UAS), which include unmanned flying platforms commonly called drones, along with associated cameras and terrain-mapping software, are a new tool in the composter’s toolbox for keeping accurate records of inventories. Specific measurement of inventories is important for accurate financial reporting because inventories are valued as assets on a facility’s balance sheet, and changes in inventories can be used to verify sales reports. They can also be used to verify enough product is on hand for large orders.

Composters whose permits limit the volumes of materials on-site at any given time can use drone inventory mapping to verify permit compliance. In addition, for services like contract grinding where the contractor is paid by the finished ground-up volume, accurate inventory monitoring helps in verifying contractor invoices. A side benefit of drone imagery is the high-resolution photos that are achievable, which can be used for promotional material or site planning purposes.

Other applications where UAS are being used include aerial topographic mapping of potential sites for organics recycling facilities where ground-based surveying would be more expensive and time-consuming and monitoring landfill compaction elevations to produce updated data on remaining available airspace capacity.

Review Of The Technology

UAS consist of the unmanned aircraft (UA) itself, and all the associated support equipment, control station, data links, telemetry, navigation and communication equipment needed to operate the drone. Unmanned aircraft consist of both rotorcraft (also known as quadcopters) and fixed-wing aircraft. Most rotorcraft will fly for 15 to 20 minutes before the batteries need to be replaced, so this makes them more suitable for flights over 1 to 100 acres. They are easier to operate than fixed-wing UAs and require less training. Fixed-wing UAs will fly for 45 to 90 minutes between rechargings and can handle both heavier equipment and more variable weather conditions. They are considerably more expensive and complicated to master.

The payload that a UAS carries is defined by the project requirements and by the capacity of the UA platform. Digital cameras, ranging from sports photography GoPros to high-end digital single-lens reflex cameras, are the most common payload, although specialized spectral sensors are used for mapping particular environmental features like wetlands. Full-motion video cameras are also available payloads, which can produce geocoded videos that can be viewed inside Geographic Information Systems (GIS) models. Not surprisingly, heavier payloads result in shorter flying times for less robust UAs.

Other factors that influence flight time of a drone include hovering versus turning/banking; hovering uses less energy, prolongs flight time and is essential to filming. Weather can influence drone flight times, too, in that flying against wind, snow, humid air and rain can drain batteries faster.

UAS Regulations

One challenge with UAS is that regulations governing their use are in flux and can vary depending on location. UAS operators need to comply with federal, state, and potentially local regulations. On the federal level, the Federal Aviation Administration (FAA) manages UAS authorizations.

If you have a small drone that is less than 55 pounds, you can fly for work or business by following the Federal Small UAS Rule (Part 107) guidelines (see summary). All owners of drones weighing between 0.55 and 55 pounds must register the drone with the FAA’s UAS registry before flying it outdoors. (Drones weighing more than 55 pounds are considered aircraft and must be registered with the federal Aircraft Registry.)

In order to fly your drone under the Part 107 rules, you must obtain a Remote Pilot Certificate from the FAA. This certificate demonstrates that you understand the regulations, operating requirements, and procedures for safely flying drones. You will also have to register your drone with the FAA, which recommends marking your drone with your registration number in case it gets lost or stolen. As of April 2021, the FAA had registered 873,265 drones and certified 224,756 remote pilots.

In April 2021, the FAA finalized the “Operations over People” rule, which allows routine operations over people and routine operations at night under certain circumstances. The rule will eliminate the need for typical operations to receive individual Part 107 certificate of waivers from the FAA. Drone pilots operating under Part 107 may fly at night over people and moving vehicles without a waiver as long as they meet the requirements defined in the rule. Airspace authorizations are still required for night operations in controlled airspace under 400 feet.

State and local regulations tend to be more focused on allowable hours of operation and privacy issues. For example, in the author’s home state of Virginia, it is a Class 1 misdemeanor to fly a drone over someone else’s property to spy on them. A summary of state drone laws can be found at this link. Some municipalities have passed ordinances against UAS operations and the number of lawsuits related to drone operations is increasing, arising out of claims of trespass and invasion of privacy.

Composter Puts Drone Into Action

One composter using drones is Dirt Hugger, a source separated organics composting facility in Dallesport, Washington. Founded in 2010, Dirt Hugger receives about 55,000 tons/year of residentially collected yard trimmings and food waste, commercial food waste (from restaurants, groceries, and schools), whole fruit waste, cherry sludge from fruit processing, beer waste and beer yeast waste (about 30,000 gallons/week), wood waste, and brush. Feedstocks come from generators throughout the Columbia River Gorge region, including the Vancouver, Washington and Portland, Oregon metro areas.

Dirt Hugger purchased a DJI Phantom 3 drone (which has since been upgraded to a Phantom 4 model). They used a software service, Maps Made Easy, which notes on its website: “Each green box that gets drawn represents an image taken by the camera. The darker the green, the more times that area has been repeatedly photographed. Ideally, the camera should be able to see every point you want to include in the map at least 14 to 18 times. By precisely controlling the flight pattern, flight speed and camera frame rate, it is possible to achieve perfect coverage and overlap. Plenty of overlap and nadir (straight down) images are the key components to collecting great data and making great maps.”

The green box that gets drawn represents an image taken by the camera. The darker the green, the more times that area has been repeatedly photographed. Image source: Maps Made Easy

Ben Brown, a former aeronautical engineer now with Dirt Hugger, earned a Remote Pilot Certificate from the Federal Aviation Administration. “We decided to go with Maps Made Easy, where a series of images is uploaded to the service,” explains Brown. “A map is generated and compared against a pre-existing GIS database. Piles are user selected and calculations are performed by the software to generate area and volumes. The Ground Sample Distance is the key parameter. A better camera (higher resolution) will result in more object definition and better maps, and you can be higher up and take fewer photos. With a lower resolution camera you’ll need to be closer to the ground and take more photos to get the same map.”

Brown adds that prior to using the drone, Dirt Hugger was using hand calculations and counting bucket loads from the front-end loaders. “Now it takes me about 1 to 3 hours to capture all the images, and to manipulate and load the data,” he says. “This investment now gets us to within 2% to 3% of pile volume, whereas before, we were maybe within 15% to 20%.” Dirt Hugger also uses the drone for predicting flow volumes, which gives them a better idea of how much product is where on-site and how much has gone where. This information allows the company to time the volume measurements with the business cycle of market sales.

Lessons in drone usage have definitely been learned. “Before you try to do your first site survey, learn to fly the drone,” notes Brown. “Practice is key in those stressful situations, especially takeoff and landing. Choose the service that best suits your needs. There seem to be quite a few companies offering essentially the same service. Drone Deploy, Propeller Aero, Sky Dirt all look similar to Maps Made Easy. You can see some are highly sophisticated — and that polished user interface costs extra. I would also say drone surveys are just one more tool in the toolbox to measure volumes. The barrier to entry is building the additional skill set of a Remote Pilot. The payback is higher confidence in your volumes and perhaps some time savings depending on how you were estimating volumes previously.”

While several controversial issues surround use of UAS in society today, for composters who track inventory value or who want to know if they can fill a large order, this advanced technology would likely pay for itself fairly rapidly. If it also can be used to help manage operations, e.g., searching for hot spots in piles, drone coverage at composting facilities could be a very valuable tool.

Craig Coker is a Senior Editor at BioCycle CONNECT and a Principal in the firm Coker Composting & Consulting (www.cokercompost.com), near Roanoke VA. He can be reached at ccoker@cokercompost.com.