The Generation 3 Concentrating Solar Power Systems (Gen3 CSP) funding program builds on prior research for high-temperature concentrating solar-thermal power (CSP) technologies. Projects focused on de-risking CSP technologies by advancing high-temperature components and developing integrated assembly designs with thermal energy storage that can reach high operating temperatures. CSP plant operating temperatures greater than 700° Celsius have the potential to reduce the cost of CSP systems by increasing the efficiency of the plant. There are several pathways to achieving higher temperatures for CSP plants—using either liquid, solid particle, or gaseous materials—and this funding program aims to identify and create a cost-effective and reliable integrated solution.

On March 25, 2021, the U.S. Department of Energy (DOE) announced that solid particles provided the most promising pathway to achieving higher temperatures in CSP plants to meet 2030 cost targets. The project is led by Sandia National Laboratories, which will receive approximately $25 million to build an integrated test facility for next-generation CSP plants that use solid particles. Learn more about the project and why it was selected.

This funding program was launched on May 15, 2018, when DOE announced it would provide $72 million in funding for this effort, which included $63 million for the Gen3 CSP competitive solicitation and $15 million for additional national laboratory support for the Gen3 CSP selectees. On May 31, 2018, DOE announced an additional $7 million for five projects selected as alternates.

Approach

Three teams will compete to build an integrated system with thermal energy storage that can efficiently receive solar heat and deliver it to a working fluid at temperatures greater than 700 °C.

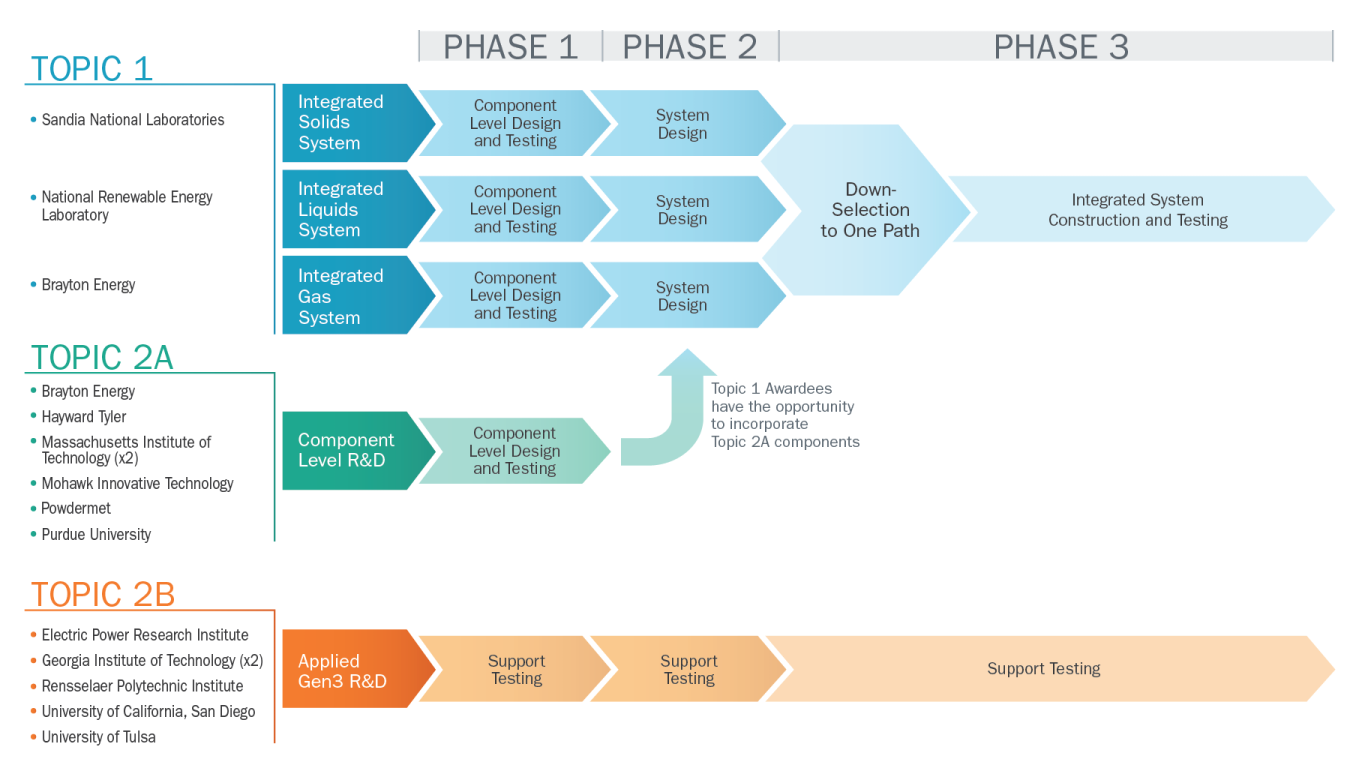

This program will progress through three interconnected phases:

- Phase 1 advances the development of specific components that have been identified as key risks in an efficient, integrated system.

- Based on the results of Phase 1, Phase 2 focused on designing an integrated system with thermal energy storage that can withstand high temperatures. Designs developed by the Phase 2 awardees went through a rigorous review and selection process.

- In Phase 3, one awardee was chosen to build a test facility that allows diverse teams of researchers, laboratories, developers, and manufacturers to test components and systems through a wide range of operating conditions necessary to advance the next generation of CSP technology.

Awards were separated into two topics:

- Topic 1 awardees performed overall integration and systems analysis and then finalized a design before down-selection to a single pathway and awardee. The selected awardee constructed a test facility and conducted research.

- Topic 2 awardees designed and built components for CSP systems and conducted cross-cutting, foundational testing to complement pathways pursued in Topic 1.

Objectives

A key to decreasing the cost of CSP plants is to raise the temperature of the heat they deliver to the power cycle in order to increase plant efficiency and lower cost. Gen3 CSP high-temperature thermal systems have the potential to lower the cost of a CSP system by approximately $0.02 per kilowatt-hour (kWh), which is 40 percent of the way toward the solar office’s 2030 cost goals of $0.05 per kWh for baseload configurations. This cost target is highly competitive with other dispatchable power generators and would enable more solar to be connected to the grid while also increasing its value.

Gen3 CSP Selections

The $62 million Gen3 CSP competitive solicitation funded 11 projects in two topic areas. Topic 1 and Topic 2B projects flowed through three phases of work, and Topic 2A flowed through two phases of work. Topic 1 awardees were able to use the components and testing developed in Topic 2A.

Selectees

-- Award and cost share amounts are subject to change pending negotiations –

Topic Area 1: Integrated Gen3 Systems

--Funding amounts listed below are for work done in Phase 1 and Phase 2. Approximately $25 million is allocated to the Topic 1 awardee selected to proceed to Phase 3: Sandia National Laboratories.--

Project Name: Gen3 Gas-Phase System Development and Demonstration

Location: Hampton, NH

DOE Award Amount: $7,570,647

Awardee Cost Share: $1,899,003

Principal Investigator: Shaun Sullivan

Project Summary: In this project, a commercial-scale gas-phase concentrating solar thermal power (CSP) system will be developed in the first two Gen3 phases and, if selected for the third phase, developed into a test facility. The megawatt-scale test system will absorb energy from a heliostat field and deliver it into a thermal energy storage system, storing nine megawatt-hours of heat at a temperature of 750 °C for a minimum of ten hours. The energy then moves into a working fluid that could have a round-trip efficiency of 99 percent, creating a CSP solution that enables on-demand renewable energy.

Project Name: Liquid-Phase Pathway to SunShot

Location: Golden, CO

DOE Award Amount: $7,035,309

Awardee Cost Share: $5,432,401

Principal Investigator: Craig Turchi

Project Summary: This team will test the next generation of liquid-phase concentrating solar thermal power technology by advancing the current molten-salt power tower pathway to higher temperatures and efficiencies. The project will design, develop, and test a two megawatt thermal system consisting of the solar receiver, thermal energy storage tanks and associated pumps, heat exchangers, piping, valves, sensors, and heat tracing. If selected for the third phase, the system will be validated in a commercial-scale test facility.

Project Name: Gen3 Particle Pilot Plant: Integrated High-Temperature Particle System for CSP

Location: Albuquerque, NM

DOE Award Amount: $9,464,755

Awardee Cost Share: $6,676,553

Principal Investigator: Clifford Ho

Project Summary: This project will design and test a multi-megawatt thermal falling particle receiver concentrating solar thermal power (CSP) system in the first two Gen3 CSP phases. It will have the potential to operate for thousands of hours, provide 6 hours of energy storage, and heat a working fluid like supercritical carbon dioxide or air to a temperature of at least 700 °C. In Phase 3, if selected, the team will validate the ability to meet the Solar Energy Technologies Office CSP cost and performance goals via a commercial-scale test facility.

Topic Area 2A: Individual Component Development

Project Name: Integrated Thermal Energy Storage Heat Exchanger for Concentrating Solar Power Applications

Location: Hampton, NH

DOE Award Amount: $1,181,603

Awardee Cost Share: $295,740

Principal Investigator: Jim Nash

Project Summary: An efficient and economical solution to charging and discharging heat from thermal energy storage (TES) media is a critical development need in order to maintain steady power production from concentrating solar power systems. This project will develop and test heat exchanger technology that can integrate with a variety of advanced TES media and systems. The performance and cost of this integrated TES will be compared to other storage technologies for possible incorporation into a Gen3 CSP Topic 1 test facility.

Project Name: Development of High-Temperature Molten Salt Pump Technology for Gen3 Solar Power Tower Systems

Location: Colchester, VT

DOE Award Amount: $2,000,000

Awardee Cost Share: $620,523

Principal Investigator: Benjamin Hardy

Project Summary: This project seeks to provide a plan to improve existing long-shafted, vertical hot salt pump technology. The team will research and develop a test rig in order to provide a recommendation for submerged bearing materials types to be utilized in a Gen3 pump design. They will also develop pump designs that can efficiently operate in the target hot and cold molten salt environments using the bearings and materials this project’s testing recommends.

Project Name: Ceramic Castable Cement Tanks and Piping for Molten Salt

Location: Cambridge, MA

DOE Award Amount: $1,771,798

Awardee Cost Share: $443,033

Principal Investigator: Asegun Henry

Project Summary: This team will develop ceramic castable cements to be used for thermal storage tanks and piping which carry and store high-temperature molten salts at 750 °C. This project is also investigating engineered high-temperature cements that can be used to form a self-insulating thermal storage tank. These ceramic castable cements are being chemically engineered to resist corrosion and penetration by the high-temperature salts of interest for the liquid pathway.

Project Name: High-Temperature Pumps and Valves for Molten Salt

Location: Cambridge, MA

DOE Award Amount: $1,932,414

Awardee Cost Share: $482,978

Principal Investigator: Asegun Henry

Project Summary: This project will develop high-temperature liquid-phase pumps and valves that use novel ceramic-metal composite materials that are stable at high temperatures, instead of steel or nickel-based alloys, to create components that can reliably operate with molten salts at 750 °Celsius. This project will use low-cost novel refractory materials and processes to form these materials into the complex shapes needed to form pump and valve components. They will test the integration of these components in both liquid pumps and valves and investigate whether any new corrosion mechanisms arise due to salts flowing through the pumps in comparison to stagnant salt. This will enable the scale-up of a liquid pump that can be implemented in a multi-megawatt flowing molten salt loop with high reliability and used in Phase 3 of the Gen3 CSP program.

Project Name: Oil-Free, High-Temperature Heat Transfer Fluid Circulator

Location: Albany, NY

DOE Award Amount: $1,258,629

Awardee Cost Share: $419,800

Principal Investigator: Hooshang Heshmat

Project Summary: The objective of this project is to develop a maintenance- and oil-free high-temperature heat transfer fluid (HTF) circulator for gas-based Gen3 concentrating solar thermal power systems through research, design, and testing. The HTF circulator will be designed for system simplicity, maintenance-free operation, high reliability, and reduced capital and operating costs by isolating the drive from the HTF and designing foil gas bearings and seals that are able to use the HTF as lubricant.

Project Name: High-Toughness Cermets for Molten Salt Pumps

Location: Euclid, OH

DOE Award Amount: $1,326,384

Awardee Cost Share: $331,727

Principal Investigator: Joseph Hensel

Project Summary: This team will develop high-toughness, ceramic-metal composite materials (cermets), which offer minimal friction in fluids with poor lubrication and are resistant to erosion and wear-and-tear. The project will build a liquid pump and a component test facility that analyzes these materials in a molten chloride salt environment, examines design allowances, and determines the cost-effectiveness of the cermets. This work could enable fabrication of low-maintenance, durable pumps for concentrating solar power systems.

Project Name: Robust High-Temperature Heat Exchangers

Location: West Lafayette, IN

DOE Award Amount: $1,960,745

Awardee Cost Share: $499,945

Principal Investigator: Kenneth Sandhage

Project Summary: This team will develop a high-performance heat exchanger based on a new ceramic-metal composite material (cermet) for transfer of high-temperature (greater than 750 °C) molten chlorides, with supercritical carbon dioxide as the working fluid for energy conversion in the power block of a concentrating solar thermal power system. The higher failure strengths and thermal conductivities at 800 °C of these cermets instead of metal alloys will allow the team to design smaller, lower-cost heat exchangers than would otherwise be possible. By tailoring the cermet surface and fluid chemistry, the cermets also have the ability to withstand thermal cycling and thermal shock, as well as resist corrosion from molten salts and fluids based on supercritical carbon dioxide.

Topic Area 2B: Gen3 Research and Analysis

Project Name: Improving Economics of Gen3 CSP System Components through Fabrication and Application of High-Temperature Nickel-Based Alloys

Location: Palo Alto, CA

DOE Award Amount: $1,499,901

Awardee Cost Share: $222,229

Principal Investigator: John Shingledecker

Project Summary: In order to reduce high-temperature concentrating solar thermal power plant costs, this team will investigate manufacturing methods for alloys that had previously been designed for high-temperature power service in advanced ultra-supercritical steam. They will examine the cost and performance advantages of manufacturing pipes and tubes from flat sheets after further processing, which can lower capital costs. If these alternate manufacturing routes of alloys can produce pipes that are able to maintain operating lifetimes similar to piping produced from other nickel-based alloys, they have the potential to reduce the cost of these components by about thirty percent.

Project Name: Advanced Characterization of Particulate Flows for Concentrating Solar Power Applications

Location: Atlanta, GA

DOE Award Amount: $1,352,195

Awardee Cost Share: $150,649

Principal Investigator: Peter Loutzenhiser

Project Summary: This project will address a knowledge gap within the field of particulate flows for concentrating solar thermal power (CSP) applications. The team will characterize the flow and heat transfer of particulate media over a range of operating conditions, including temperature, particle size, and construction material. Through experimentation and modeling, the team will determine the properties needed for inputs at these high temperatures. These results will provide guidance to the CSP industry for ongoing work related to the design and modeling of solar particle heat receivers and reactors.

Project Name: Thermophysical Property Measurements of Heat Transfer Media and Containment Materials

Location: Atlanta, GA

DOE Award Amount: $1,966,440

Awardee Cost Share: $218,494

Principal Investigator: Shannon Yee

Project Summary: This project will research and analyze the thermophysical properties supporting the Gen3 integrated thermal system. This team will look at thermal conductivity, thermal diffusivity, and specific heat across the range of temperatures and materials of interest to Gen3 CSP systems. The team will perform measurements on molten salt chemistries proposed by topic area 1 awardees, and containment materials, including the alloy, ceramic, and cermet materials proposed by awardees in topic areas 1 and 2A. This research will be shared to address the knowledge gap in Gen3 thermophysical properties.

Project Name: Development of In-Situ Corrosion Kinetics and Salt Property Measurements

Location: Troy, NY

DOE Award Amount: $1,799,892

Awardee Cost Share: $200,107

Principal Investigator: Li (Emily) Liu

Project Summary: This project will develop in-situ experimental techniques and methodologies to gain a fundamental understanding of the mechanisms of molten-salt surface corrosion kinetics and molten-salt properties. Four complementary approaches will be developed to achieve these objectives: in-situ transmission electron microscopy; neutron reflectometry of molten salt and alloy cells; macroscopic electrochemical studies; and vibrational spectroscopy analysis and modeling. By addressing the knowledge gaps in high-temperature molten-salt properties and corrosion mechanisms, this research can guide the selection of salts and containment materials.

Project Name: Non-Contact Thermophysical Characterization of Solids and Fluids for Concentrating Solar Power

Location: La Jolla, CA

DOE Award Amount: $1,180,000

Awardee Cost Share: $137,000

Principal Investigator: Renkun Chen

Project Summary: This team will develop a non-contact characterization technique called modulated photothermal radiometry (MPR). The technique will measure the high-temperature thermophysical properties of heat transfer fluids and the associated solids, like tubing and solar absorbing coating, in various components and sub-systems used in concentrating solar power (CSP) plants. The MPR technology can provide low-cost and fast characterization of heat transfer fluids and solids for Gen3 CSP facilities.

Project Name: GEN3D – Experimental and Numerical Development of Gen3 Durability Life Models

Location: Tulsa, OK

DOE Award Amount: $1,515,687

Awardee Cost Share: $201,743

Principal Investigator: Todd Otanicar

Project Summary: This team will develop a comprehensive particle and substrate durability model that will enable improved understanding of the performance of high-temperature components for the particle-based pathway. The team will advance existing research capabilities in erosion, corrosion, fracture mechanics, macro- and micro-scale materials characterization, and thermal and optical property characterization. The results will be used to develop a broad understanding of mechanical durability that can be used to determine component lifetime and performance degradation models.

Learn more about the solar office's other concentrating solar power awards.

Gen3 CSP Lab Call Selections

In support of the Gen3 CSP competitive solicitation, the office provided an additional $10 million in funding to national laboratories to bolster this effort. These lab projects supplied the facilities and material testing needed to remove critical knowledge barriers and prove the viability for the Gen3 CSP pathways. Projects aimed to discover and characterize essential material properties and also provide a lab-scale facility to test the Gen3 CSP materials, components, and systems. Selected labs built and operated test loops to provide the high-temperature operating conditions needed to validate pathway concepts and material combinations, helping to identify lower cost materials, reduce component damages, and enable integrated assembly designs to withstand high temperatures.

Laboratories

Idaho National Laboratory

Project Name: Creep-Fatigue Behavior and Damage Accumulation of a Candidate Structural Material for CSP Solar Thermal Receiver

Location: Idaho Falls, ID

DOE Award Amount: $1,000,000

Principal Investigator: Michael McMurtrey

Project Summary: To address a critical challenge for Gen3 CSP gas receiver designs, this project will provide a detailed analysis of the creep-fatigue behavior and resulting component damage for a concentrating solar thermal power (CSP) thermal receiver. Creep-fatigue deformation is an important consideration for a gas-phase CSP system thermal receiver due to the constant static stress or pressure, daily cycling, and elevated service temperatures required for efficient operation. The project will also create a roadmap for the design of solar receiver components able to withstand high-temperature creep-fatigue and ratcheting failure.

National Renewable Energy Laboratory 2

Project Name: Molten Chloride Thermophysical Properties, Chemical Optimization, and Purification

Location: Golden, CO

DOE Award Amount: $1,000,000

Principal Investigator: Judith Vidal

Project Summary: This team will address the thermophysical properties and handling of molten chloride salts that can be used as both the heat-transfer fluid and thermal energy storage material. They will investigate the purification of commercial salts, optimization of chemical composition, and handling procedures for concentrating solar thermal power applications. They will also create and publish guidelines and protocols needed for obtaining accurate and reliable thermophysical properties of molten chloride salts.

Oak Ridge National Laboratory 1

Project Name: Comparison of Protecting Layer Performance for Corrosion Inhibition in Molten Chloride Salts through Interfacial Studies at the Molecular Scale

Location: Oak Ridge, TN

DOE Award Amount: $955,000

Principal Investigator: Carter Abney

Project Summary: Molten chloride salts easily corrode internal structures for concentrating solar thermal plants when it’s used as a heat transfer fluid, representing a significant barrier to the technology’s commercialization. This project will prepare a series of material samples similar to a solar receiver structural alloy in contact with a chloride-based salt. These samples will be studied to investigate the in-situ structure of these interfaces. The results of these studies will guide strategies for corrosion mitigation and the design of concentrating solar thermal power plants for Gen3 CSP awardees.

Oak Ridge National Laboratory 2

Project Name: Enabling High-Temperature Molten Salt CSP through the Facility to Alleviate Salt Technology Risks

Location: Oak Ridge, TN

DOE Award Amount: $4,300,000

Principal Investigator: Kevin Robb

Project Summary: This project focuses on the design, construction, and operation of a lab-scale test facility to alleviate salt technology risks (FASTR). FASTR is a versatile high-temperature molten chloride salt facility designed for temperatures greater than 700°C and for a variety of testing in support of the Gen3 CSP molten salt pathway. FASTR and the accompanying research will provide the foundational capabilities necessary to support Gen3 CSP awardees.

Oak Ridge National Laboratory 3

Project Name: Progression to Compatibility Evaluations in Flowing Molten Salts

Location: Oak Ridge, TN

DOE Award Amount: $1,000,000

Principal Investigator: Bruce Pint

Project Summary: To accelerate the testing of compatible alloys with molten chloride salts, this project will identify the salt-alloy combinations that are compatible in isothermal capsule tests and then conduct thermal convection loop (TCL) experiments with a peak temperature at or greater than 700°C and a typical temperature gradient of 75° to 100°C. Subsequent TCL experiments will explore higher temperatures, different alloys, corrosion inhibition strategies, and deploy sensors to monitor salt and alloy properties.

Sandia National Laboratories 2

Project Name: Characterization of Radiative, Convective, and Particle Losses in High-Temperature Particle Receivers

Location: Albuquerque, NM

DOE Award Amount: $1,031,070

Principal Investigator: Clifford Ho

Project Summary: This project will reduce particle and heat losses in directly irradiated high-temperature (greater than 700°C) particle receiver systems, using a combination of computer simulations and measurements of particle fluid dynamics and heat transfer pathways. This will enable increased receiver thermal efficiencies, reduce receiver costs, and mitigate potential health risks from inhalation of fine particles.

Sandia National Laboratories 3

Project Name: Particle Heat Transfer Mechanisms

Location: Albuquerque, NM

DOE Award Amount: $455,000

Project Summary: In CSP plants, sunlight heats a material—solid particles, a liquid, or gas—that transfers heat from the receiver to generate power. This material is fed into a heat exchanger that moves the energy to a working fluid, such as supercritical carbon dioxide (sCO2). This project will measure the heat-transfer properties of densely packed solid particles to see how much heat from the sun they can absorb and how well they can transfer it. The results will enable improved designs for CSP plants that use sCO2 cycles, which are more efficient than traditional steam turbines and lead to lower electricity costs.

Sandia National Laboratories 4

Project Name: Supercritical Carbon Dioxide Loop in Support of the Gen3 CSP Solid, Liquid, and Gas Pathways

Location: Albuquerque, NM

DOE Award Amount: $3,600,000

Project Summary: To achieve higher efficiencies, concentrating solar power plants can use the Brayton power cycle, an engine design that uses supercritical carbon dioxide (sCO2) as a fluid to transfer heat. Current CSP plants use steam Rankine cycles, in which 35% to 42% of the collected heat is converted to electricity. Brayton power cycles that use sCO2 as the working fluid could increase this efficiency to 50% or above. This project will develop a sCO2 support loop to cool the main heat exchanger in a pilot plant project in Topic 1 of the Gen3 CSP funding program.

Savannah River National Laboratory

Project Name: Full Loop Thermodynamic Corrosion Inhibition and Sensing in Molten Chloride Systems

Location: Jackson, SC

DOE Award Amount: $1,000,000

Principal Investigator: Brenda Garcia-Diaz

Project Summary: This team will address knowledge gaps in molten salt corrosion in heat transfer loops using molten chlorides at or greater than 750°C. They will focus on adapting and tailoring high-temperature corrosion mitigation strategies to the Gen3 temperature range of between 500° and 750°C and Gen3 system designs. Potential optimizations in this temperature range will be identified in order to use lower cost structural alloys and maintain long CSP plant component lifetimes.

Learn more about the solar office's other laboratory funding.